| 936 Lancaster Road |

|

Manheim, PA 17545 |

| 1-410-238-3102 |

|

|

|

STORE HOURS M, Th 9:00am – 9:00pm Tu, W, F, S 9:00am – 5:00pm Closed Sunday |

1-410-238-3102

Surdiac Coal Stove Parts & Accessories

When you call, we will need to know these three things:

1 Does your stove have 1 or 2 ash pans?

2 Is the pyrex door Strips of 1" glass or a single pane of glass?

3 Is your hopper removable?

These answers help us determine if you have a Small, Medium, Mid-size, or Large stove.

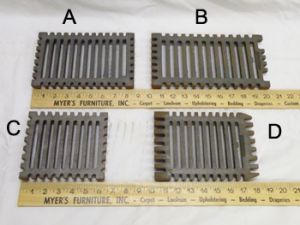

A. Large Left Grate (1 713,616,720 L)

A. Large Left Grate (1 713,616,720 L)

B. Large Right Grate (1 713,616,720 R)

C. Medium Left Grate (1 513,612,520 L)

D. Medium Right Grate (1 513,612,520 R)

A. Left and Right Grate for #715 stove

A. Left and Right Grate for #715 stove

(Large). (1 715 LEFT) (1 715 RIGHT)

B. Left and Right Grate for #515 stove

(Medium) or #466 stove small).

(1 515 LEFT) (1 515 RIGHT)

A. Cradle for grates for midsize and

A. Cradle for grates for midsize and

large stoves. (1 716,616,720 C)

B. Cradle for grates for medium stoves.

(1 513,612,520 C)

A. Ash pan for small and medium sized

A. Ash pan for small and medium sized

stoves. (1 513,612,520)

B. Ash pan for midsize and large sized

stoves (these require 2 pans).

(1 713,616,720 A)

A. Furnace paddle (left and right) for a

A. Furnace paddle (left and right) for a

midsize or large stove.

(2 LARGE LFP) (2 LARGE RFP)

B. Furnace paddle (left and right) for a

small or midsize stove.

(2 MEDIUM LFP) (2 MEDIUM RFP)

A. Fire Basket front and rear for midsize

A. Fire Basket front and rear for midsize

or large stoves.

(2 LARGE FFB) (2 LARGE RFB)

B. Fire Basket front and rear for small and

medium stoves.

(2 MEDIUM FFB) (2 MEDIUM RFB)

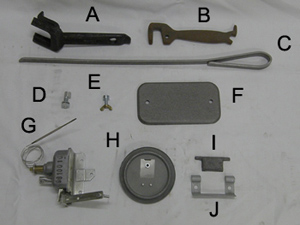

A. Cast Hand Tool for #515 or

A. Cast Hand Tool for #515 or

#715 stove. (5 TOOL 5/715CHT)

B. Cast Hand Tool for all other stoves.

(5 TOOL CHT)

C. Riddle Bar for all stoves.

(5 TOOL RB)

D. Latch Catch for Pyrex glass or ash

pan door. (5 HANDLE ELCS)

E. Butterfly and Butterfly Screw for

heatexchanger cleanout plate.

(4 CLEANOUT N&S)

F. Heat Exchanger clean out plate.

(4 CLEANOUT CAST)

G. Mayer thermostat - fits all stoves

(5 MAYER VALVE)

H. Mayer thermostat valve.

(5 MAYER VALVE)

I. Ash Removal Flap. (5 ASH REMOVAL F)

J. Ash Removal Flap Hinge. (5 ASH REMOVAL)

A. Handle to slide right grate

B. Ash Pan Door Handle

C. Thermostat Knob

D. Furnace Cement (Retort)

E. High Temperature Black Paint

F. Pyrex Glass Door Handle

G. Cast flue outlet for heat exchanger

Stove Pipes

Stove Pipes

A. 5” x 24 gauge Barometric draft regulator

(7 BARO REGULTR)

B. 5” x 24 gauge Elbow adjustable 0 - 90°

(7 ELBO-ADJUST90)

C. 5” cast manual damper.

(7 KEY DAMPER)

D. 5" x 24” 24 guage stove pipe.

(7 24" PIPE)

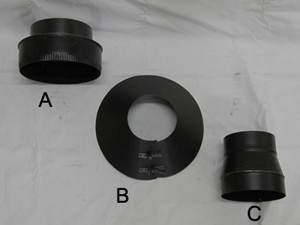

A. Reducer 8” to 6” 24 gauge.

A. Reducer 8” to 6” 24 gauge.

(7 REDUCER 8-6)

B. 5” x 24 gauge Clamping Collar

(7 PIPE COLLAR C)

C. Reducer 6” to 5” 24 gauge.

(7 REDUCER 6-5)

Medium heat exchanger

(4 MEDIUM HE)

Midsize or Large heat exchanger.

(4 LARGE HE)

Pyrex Glass for #715 stove.

(3 GLASS FOR 715)

Pyrex Glass for #515 stove.

(3 GLASS FOR 515)

One Inch Pyrex Glass for medium,

midsize, and large stoves.

(3 GLASS STRIPS)

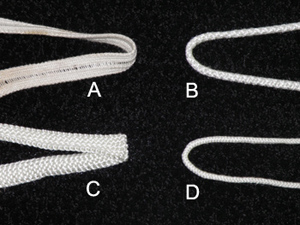

Gasket Material

Gasket Material

A. Foldable gasket 1 inch Pyrex glass.

(3 FOLDED WHITE)

B. 3/8” rope gasket.

(3 3/8" GASKET)

C. Flat gasket.

(3 1" FLAT GSKT)

D. ¼” rope gasket.

(1/4" GASKET)

Removeable half hopper for Medium stove

models 512, 612, 513, 520 (stove takes

two halves)

(2 513,612,520)

Removeable half hopper for medium

model 515 & small model 466 stoves

(stove takes two halves)

(2 515)

Removeable half hopper for Large

model 516, 616, 713, & 720 stoves

(stove takes two halves)

(2 713,616,720)

Removeable half hopper for Large

model 715 Stove (Stove takes two halves)

(2 715)

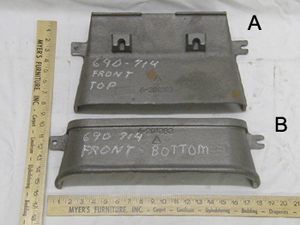

Back Half Non removeable Hopper for

690 & 714 stove

A. Top Front Half Non removeable

Hopper for 690 & 714 stove

B. Bottom Front Half Non removeable

Hopper for 690 & 714 stove

Surdiac Coal Stove 'TIPS'

"Breaking In” Season Your New Cast Iron Parts

A cast iron stove should be "broken In” much in the same way a new car with a cast iron

engine is: gradually. After installing new cast parts from Myer’s Furniture, it is mandatory that

five consecutive individual small coal fires be built in the stove prior to using it continuously

with the hopper fully loaded. The five "firings” are successive small coal fires being built with

a complete cooling off of the stove to room temperature after each fire has gone out. It is not

acceptable to build a small fire and keep it going for 2 - 3 days on a low stove setting. The

stove must be cooled off completely after firings in order to properly heat treat all the metal

parts on the stove. Only fill the stove with coal into the hopper about an inch with the

thermostat set no higher then 1 – 2.

Alternet Method to Season New Small Cast Iron Parts: Preheat oven at 325 degrees. Place

cast iron on rack. Every 30 minutes increase the temperature by 25 degrees until the oven is

maxed out. DO NOT TOUCH THE CAST IRON! IT WILL BE VERY HOT!! Let the cast iron cool

to room temperature. Repeat the process to increase the temper of the metal.

These steps should be taken in order to prevent premature damage of new cast iron. This will

harden the cast iron for a full burn.

Gaskets

Gasket material is very durable, gets dirty and old looking, but has been known to last over 25

years. A pressure impression does not indicate the need for replacement, but, a piece or section

of gasket missing, worn thru or loose and out of position does. A loose and out of position

gasket can often be corrected by using a thin coat of retort/furnace cement as a bonding agent.

If the impression in the Pyrex or ash door gasket is so deep that the door can be compressed

after latching, adjusting the latch catch will generally be the fix rather then replacing the gasket.

Gaskets are intended to "seal the gap” between two metal pieces, but are not intended to hold

pressure. If you decide a gasket needs replacing, you can purchase them from Myer’s Furniture.

Glass Cleaning

Do not attempt to clean the glass when it is hot. Allow it to cool and wipe with a cloth and a

vinegar water solution. Do not scrape the glass with anything or use any abrasive materials.

Scratches made in the glass can later develop into cracks. Replace cracked or broken glass with

4mm ceramic replacement glass from Myer’s Furniture.

Thermostat Adjustment

The thermostat senses changes in the stove operating temperature and opens or closes a valve

in the rear of the stove, regulating the amount of air the fire receives. The thermostat dial, on the

right hand side of the stove, has been set in the factory and is not to be adjusted except by a

qualified technician. Do not force the thermostat dial; turn it only as far as it will naturally go.

When the stove is hot, the dial will not go back to zero. The thermostat should be set as follows:

0 – 1 Mild temperature or nighttime use, 1 – 2 Normal usage, 3 – 4 Cold weather usage, 5 – 8 High

heat setting. Do Not Use the High Settings for a duration of more than Two Hours. After

operating in this high range for two hours, the stove must be operated at a setting of 3 or less

for the next 24 hours.

Keeping the Fire Burning

Ash that forms around coal as it is burning needs to be physically removed. This will need to

be done about every 12 hours on low settings and every 6 hours on medium to high settings.

Open the glass door using your poker to push the ash down along the edge of the fire basket

on each side and along the front. Close the glass door before starting the riddling process and

open the ash pan door. You will be looking for a live coal red reflection in the ash pan while

riddling to know when the ash has been removed allowing the live red coal to rest on the grates.

There are 3 openings above the ash door where the poker must be inserted in order to shake

down the ashes. When you introduce the poker into each opening, use a sawing motion, starting

in one of the front corners of the fire box sawing your way across the fire box to the other front

corner. Be sure to get the corners of the fire box cleaned out and that you are poking the whole

way to the back of the fire box. If the ashes are not thoroughly removed, less space will be

available for coal combustion resulting in less heat. Do not employ a side-to-side swaying

motion when shaking the stove down because it will result in live and new coal mixing with the

ash making it harder to push the poker to the back of the fire box before all the softer ash has

been removed. After shakedown, the coal hopper should be refilled. Removed ashes should be

poured into a metal container awaiting disposal.

A coal fire burns from the bottom up through the pile of coal leaving ash on the bottom, then

live coal, then new coal on the top. Ideally, your riddling process should cause the ash on the

bottom to drop through the grates allowing the undisturbed live coal to settle down to the grates

with new coal flowing from the hopper as it fills in the top of the firebox area.

Often the coal bed will not have burnt evenly from side to side causing the need for more

riddling in areas so that an even red refle